It is not so hard to imagine an extremely small robot with flexible shape

In the case of existing systems, the space next to the tool loading turnstile is narrow and limited to what is just necessary for the operator. Furthermore such area is frequently occupied by non removable objects like i.e. pillars or channels.

STAHL-2 easily finds the place to install. It is relatively small because storage is not straight but circular and split into multiple stations, each of them displaceable in accordance with existing slitters specific layouts.

Fear it’s not feasible in your facility? Let us do a study first!

No more bottle-necks in your slitter working

…with extremely fast tooling preparations.

Clean tools as a guarantee of high quality product

When cut quality and strip tolerance are of paramount importance all tools must be well cleaned.

STAHL-2 solution is a full automatic washing machine.

Loaded by robot, it provides tools multiple cleaning using heat, detergent and ultrasonics.

In few minutes the entire dirty tool set, unloaded from the turnstile, is perfectly cleaned up.

Sometimes cut quality makes the difference!

Cut quality doesn’t depend only upon precision in knives positioning and correct gaps. Knives sharpening is a mandatory requirement in case of high resistance steel.

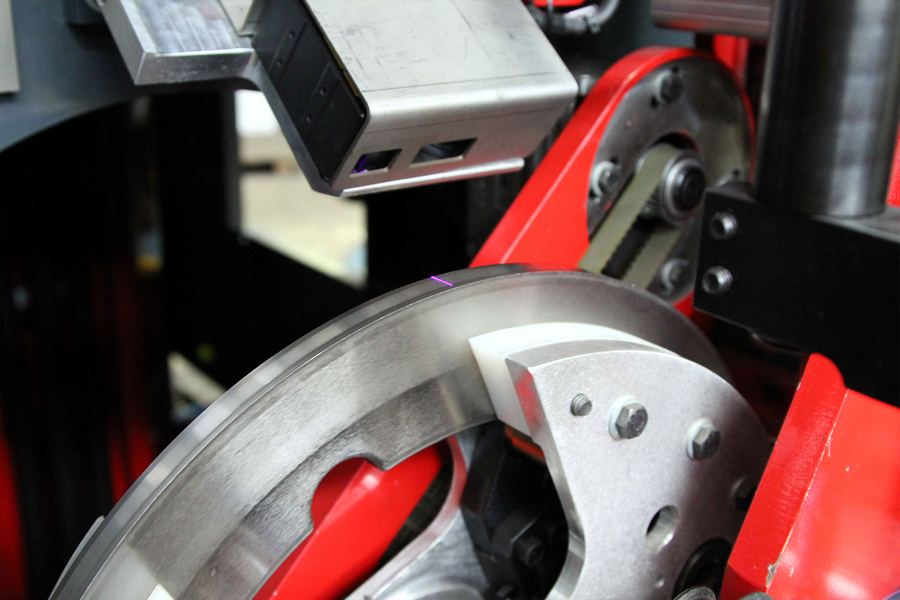

STAHL-2 takes care of cut quality without disregarding costs deriving from too frequent knives grinding. Through a fully automatic cycle, robot loads knives onto a measuring station that reads cutting edge wear with resolution and repeatability up to 5 μm and re-classifies tools.

According to Production Order data -directly retrievable from Client ERP or manually entered by operator- STAHL-2 selects most suitable knives among those available in storage. Selection criteria are totally customizable by the user who can give priority to quality or to wear equalization or set any possible intermediate conditions.

No more knife defect prints on your product!

Defected knives are never re-used. After working a fully automatic cycle unloads all knives from the turnstile and singularly checks them to detect the presence of defects, even 50 μm small.

When defects are too large, knife affected side is classified as “to grind”.